With PRESS-CHECK, you can safely and efficiently monitor both the temperature and the positioning of sheet metal during press hardening.

Thermography in Use in Press Hardening

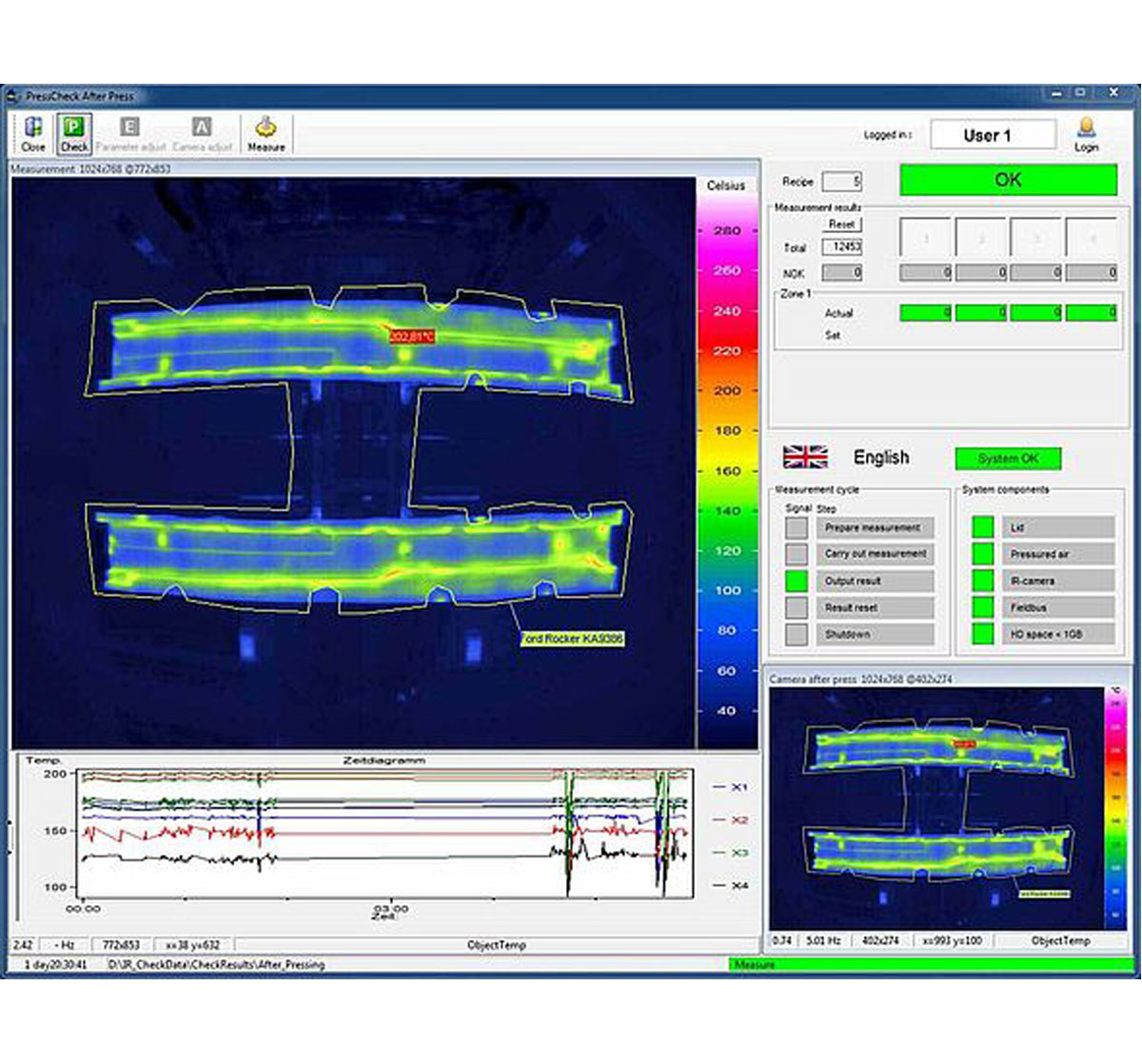

The automated test system PRESS-CHECK works with two powerful high-end thermographic cameras for continuous measurement of two-dimensional temperature distribution. This measurement is carried out before the pressing operation on the surfaces of the boards to be processed and subsequently on the resulting molded parts, ultimately enabling exact compliance with the thermal process parameters.

As a result, you get components with the designed microstructure and a corresponding local resistance distribution. A consistently high production quality is ensured by the thermographic-based, two-dimensional monitoring of process temperatures, with distinct advantages over merely selective temperature measurements on reference points offered by pyrometers, for example.

The process-specific temperature limits for the differently shaped metal parts can be managed in special recipes. Stampings with different thermal signatures are recognised and can be automatically sorted out, so your wastage rates fall considerably. Furthermore, the software checks whether a sheet is inserted into the press, checks how it is positioned and recognises double sheets. If necessary, the press is stopped automatically.

Features and Benefits

PRESS-CHECK Software