Thermographic Fire Prevention in Waste Bunkers

WASTE-SCAN Supports Fire Protection in Waste Bunkers

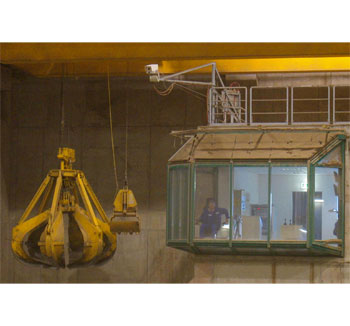

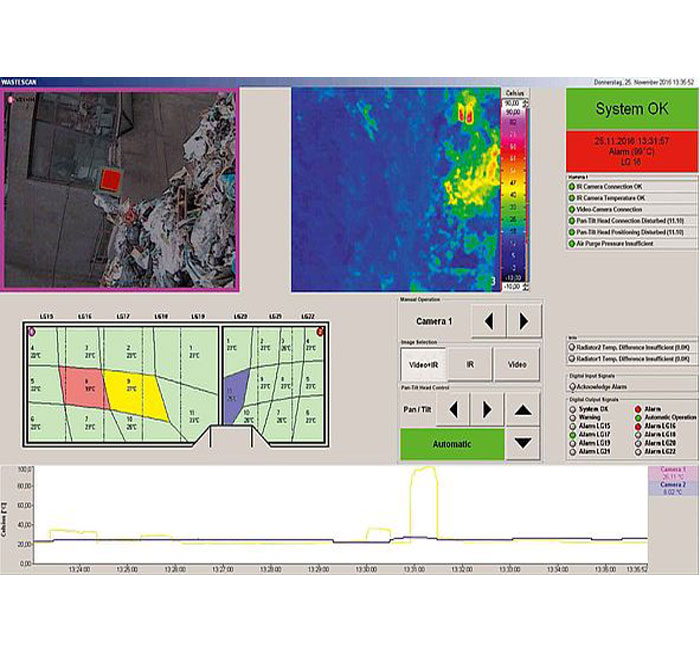

Waste incineration plants are subject to fire safety regulations since it can cause danger to environment and its local residents. Thus, InfraTec offers its thermographic solution WASTE-SCAN in particular with regard to the 17th German federal immission protection ordinance for early fire detection and fire fighting. It is a consistent further development of the FIRE-SCAN system for the special needs in the waste and power industry on the operation of waste bunkers. The application of WASTE-SCAN reduces the danger of fire in waste bunkers and, therefore, the escape of toxic gases. A fully remote-controlled solution from the bunker control room or the crane cockpit enables a flexible work for plant operators. When necessary, they are additionally supported by a camera for a better orientation. Critical temperature areas can be displayed directly in the visual image. The infrared camera itself is enclosed in a robust housing with a blow-off system for the camera lens and, therefore, can also operate under adverse ambient conditions.

Powerful WASTE-SCAN-Software